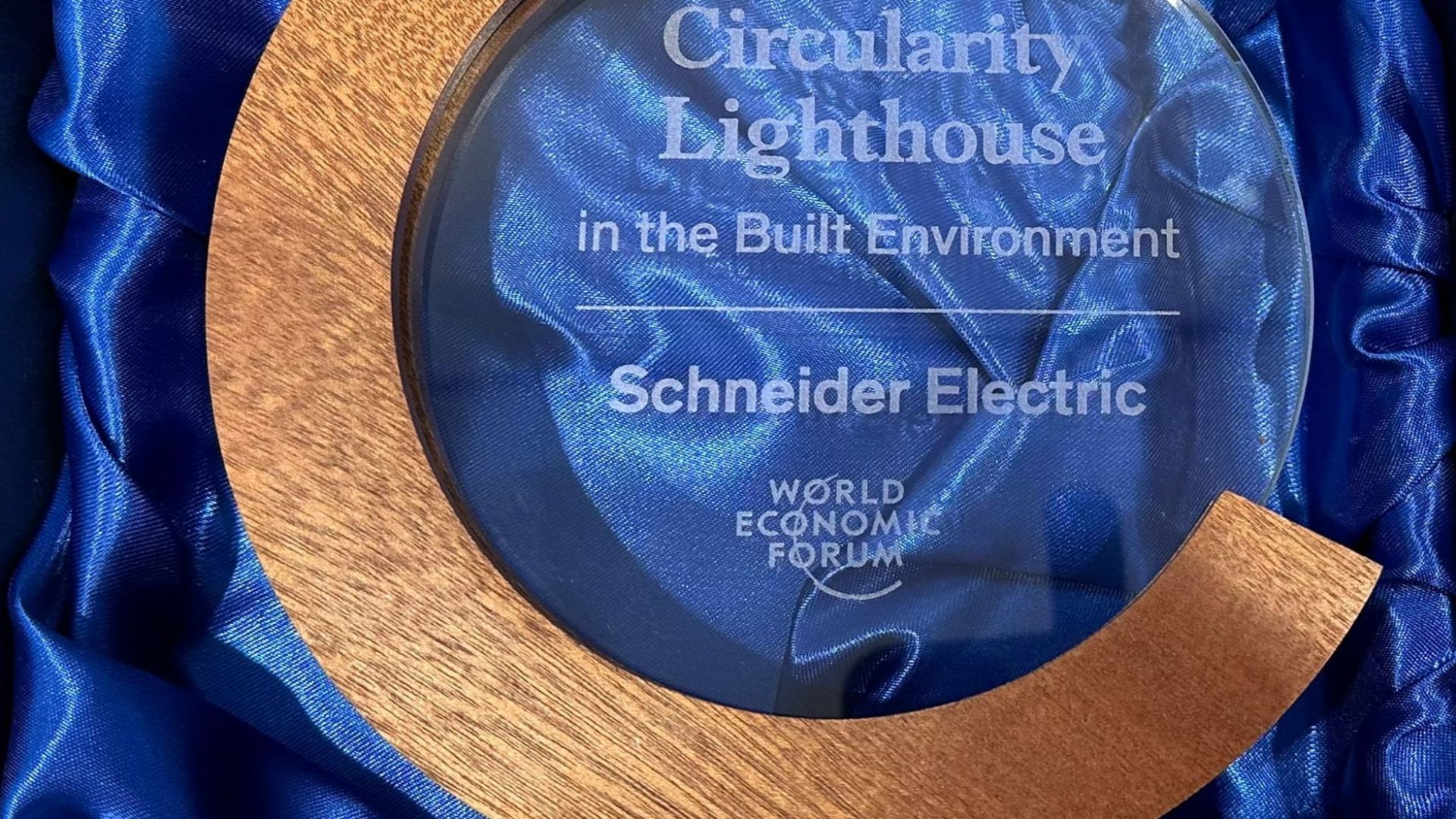

Schneider Electric, the leader in the digital transformation of energy management and automation, today announced that it has been recognized by the World Economic Forum and McKinsey as one of three global Circularity Lighthouses in the built environment.

This new designation recognizes pioneering circularity solutions that demonstrate innovation, substantial impact and value, and maturity of scale. The new lighthouses were selected by an independent panel of experts from industry, academia, and public life.

The World Economic Forum defines the built environment as residential and commercial infrastructure. Together, this is responsible for 39% of energy-related CO2 emissions, 33% of material consumption and waste generation, and 25% of land system change. The Forum’s Circular Lighthouse network provides companies a way to share and learn from one another to rapidly accelerate action and scale for greater resource efficiency.

Schneider Electric was recognized by the World Economic Forum and McKinsey for its end-to-end circular approach across a broad portfolio of its energy and building automation solutions. Through eco- design, waste-to-resources sites, and a global network of refurbishment centers, Schneider Electric has avoided approximately 513 million tons of CO2 to customers since 2017.

The company also uses 27% green materials across its products with the ambition to reach 50% by 2025. 22% of Schneider Electric’s product families have a circularity option, and more than half of Schneider Electric’s manufacturing sites recover more than 99% of waste.

“Circular business models offer compelling sustainability and commercial benefits,” said Peter Herweck, Schneider Electric’s Chief Executive Officer. “We look forward to the opportunities this new Circularity Lighthouse network offers to learn, share, and accelerate action.”

One example is how Schneider Electric gives its MasterPact MTZ circuit breakers a second life. Refurbished at the MasterTech plant in France, these circuit breakers are collected from customers at the end of life, disassembled, diagnosed, upgraded and tested before being put back on the market.

At the recent World Economic Forum’s annual meeting in Davos, Switzerland, Herweck also urged that greater deployment of existing technologies is needed to keep climate change from spiraling out of control.

“With energy accounting for 80% of carbon emissions, the energy transition is central to decarbonization. The potential of AI is currently capturing everyone’s attention. But let’s not forget that existing technologies – both renewable energy generation and digital and electrification tools that lower energy demand by rendering sites and operations far more energy efficient – can sharply reduce emissions now. There’s no time to wait for tomorrow’s solutions when much more can be achieved with what we have today,” he added.

IMPACT Supply Chain Program

Circular business models and supply chain design are part of Schneider Electric’s IMPACT Supply Chain program. This is the next evolution of the company’s supply chain transformation, which aims to make a positive impact on both customers and planet. Its key pillars are:

- People – Schneider’s people are empowered to innovate and make a positive impact for customers every day.

- Planet – Schneider Electric is building a sustainable, responsible, and net-zero ready supply chain.

- Customers – Schneider Electric’s reliable supply chain delivers industry-leading quality.

- Performance – Schneider Electric drives performance through advanced technology, smart and unified processes, regional ecosystems, and collaborative design.

Related resources:

- Youtube: New Business Model for Circular Economies: MasterPact MTZ

- Press release: World Economic Forum recognized Schneider Electric’s Hyderabad factory as a Sustainability Lighthouse

- Blog: EcoDesign: The future of Life Cycle Assessment in sustainability

- Schneider Electric Smart Factory

- For a full list of Schneider Electric’s awards and recognitions, click here